The Production Effort Unit (UEP) is a methodology used to measure efficiency and productivity in industrial environments. Developed in the 1960s by the French engineer Jean Charles André, the UEP's primary objective is to standardize the effort required to manufacture different products, allowing for a fair comparison between them and facilitating production control.

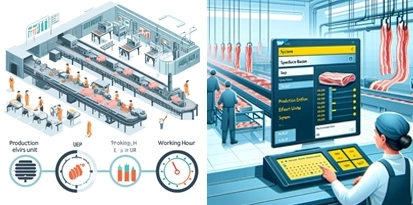

The UEP transforms the production of various items into a common unit called the Production Effort Unit. To do this, the production effort required for each stage of a product's manufacturing process is analyzed, considering factors such as operation time, labor, energy consumption, and machine use. This effort is quantified and converted into UEPs, creating a unified measurement system.

The implementation of the UEP begins with a detailed analysis of production processes, where each operation, the resources involved, and the execution times are identified. Next, the specific effort for each operation is determined in terms of time, energy, and labor, converting these efforts into a common metric. The specific efforts are then converted into UEPs using a predefined conversion factor, determined based on a detailed analysis of the factory and production processes. Finally, the total production in UEPs is calculated, allowing a clear view of production capacity and performance.

The advantages of the UEP include standardizing production effort measurement, facilitating the comparison of different production lines and products, identifying bottlenecks and inefficiencies in the production process, and improving production control and management, allowing precise adjustments to optimize resources and increase productivity.

A specific example of the UEP's application is its use as a unit of measurement in slaughterhouse production schedules, particularly in the SAP Meat and Fish Management by msg solution. In this context, the UEP standardizes and measures the effort required at each meat and fish processing stage, from slaughter to packaging. This allows for more precise production control, helping to identify inefficiencies and optimize resources, resulting in a more efficient and productive operation.

Difference Between UEP and HR in the SAP System

In the SAP system, the traditionally used unit of measurement is the Working Hour (HR). The HR measures the total time required to complete a task or operation. In contrast, the UEP considers time and other resources such as energy and labor, providing a more holistic view of the production effort.

Changes in the Day-to-Day of the Employee

Using UEP instead of HR will bring several changes to the day-to-day of employees in the SAP system:

1. Data Recording: Instead of recording only the time spent on each operation, employees will need to record additional information, such as energy consumption and machine use.

2. Production Analysis: Efficiency and productivity analysis will become more detailed, allowing for the identification of not only where time is spent but also how other resources are utilized.

3. Planning and Control: Production planning will be more precise since the UEP provides a complete view of the required resources. This will allow for better control over costs and resource utilization.

4. Identification of Inefficiencies: The UEP will help identify not only time bottlenecks but also energy and machine use inefficiencies, enabling more comprehensive improvements in production processes.

In summary, the transition from HR to UEP in the SAP system provides a more complete and detailed approach to production management, allowing for more effective resource optimization and continuous productivity improvement.