Optimize dairy product portfolios across raw material networks with SAP Dairy Management and SAP Profitability and Performance Management

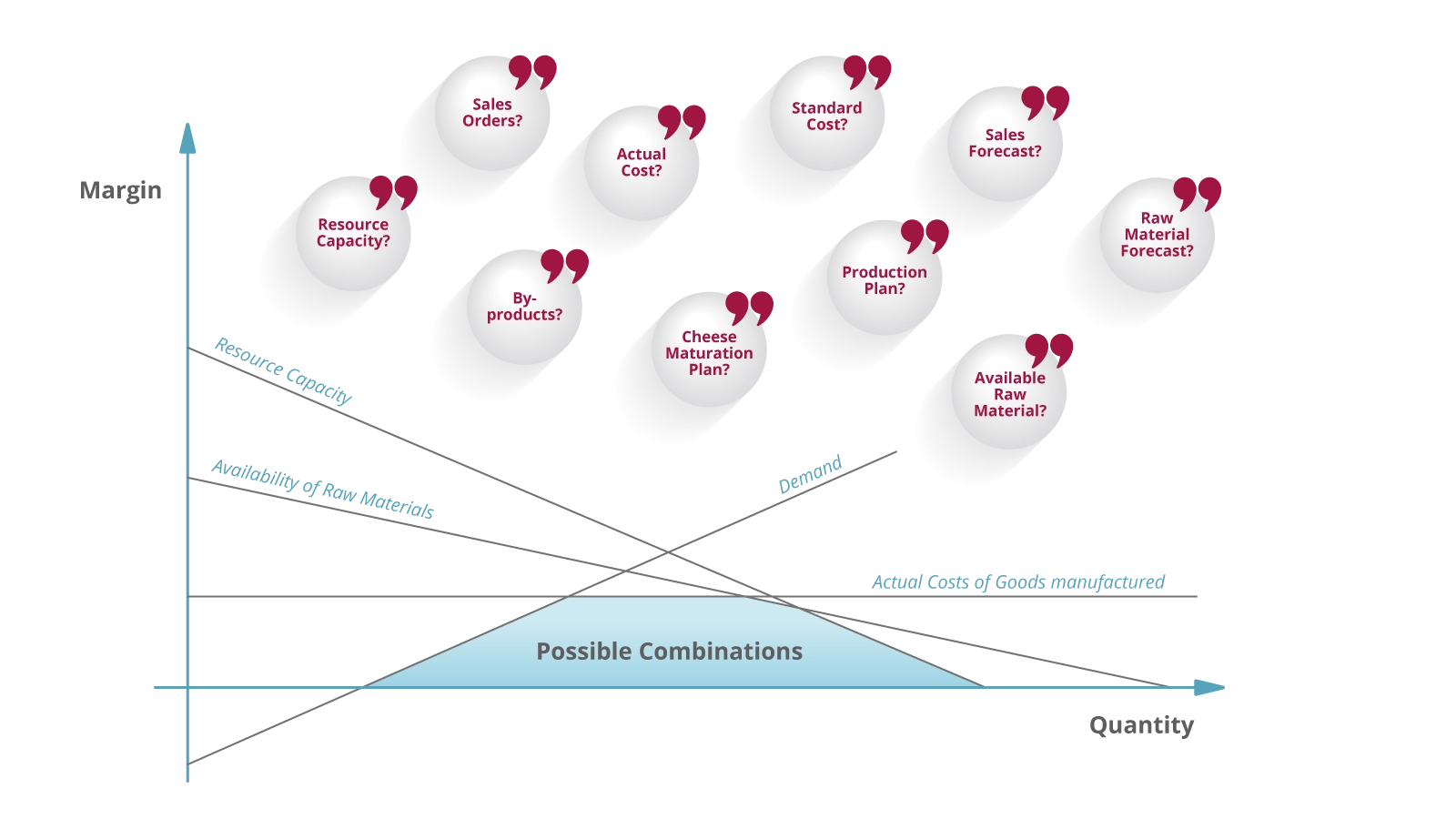

The crucial question for the Dairy Industry is this: “Given the milk I have available at a given point in time, how can I maximize its yield and my profitability?” It sounds simple, yet two key hurdles often stand in the way of answering this question efficiently and promptly:

First, significant time is typically spent on manual efforts to merge de-coupled business processes and heterogeneous information systems, which prevents timely analysis and optimization. This hurdle is best overcome with SAP Dairy Management. SAP Dairy Management automates dairy-specific materials management processes, including the determination of COGS, based on the milk sub-components.

Second, the cost and margin transparency provided by SAP Dairy Management needs to be leveraged to optimize product portfolios across raw material networks under the constraints of supply, capacity, costs, margin, demand, and other factors.

This second hurdle is best overcome with msg global’s Optimizer for Dairy Raw Material Utilization (powered by SAP Profitability and Performance Management — SAP PaPM) which performs a constraint-based, iterative profit-optimization of product mixes.

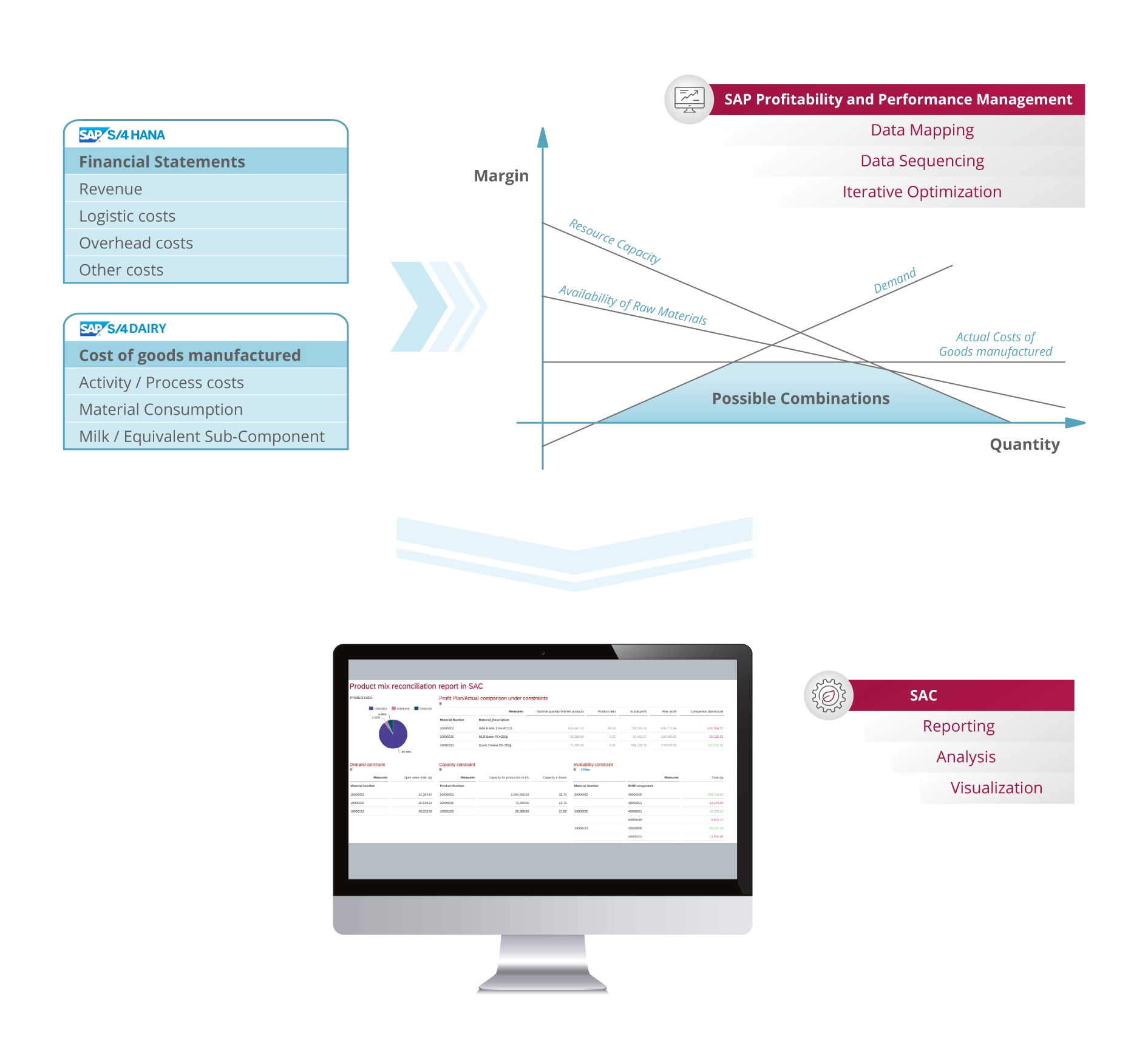

Initially, the Optimizer for Dairy Raw Material Utilization integrates (a) material balances and consumption, contribution margin, production cost, and other elements at the sub-component level from SAP Dairy Management and (b) revenue, supply, and distribution cost, and capacity and demand (by tracking open sales orders) from S/4HANA. Then — because our product mix needs to be optimized under the constraints of consumption (from SAP Dairy Management) and demand and supply (from S/4HANA) — it converts data to a common unit of measure.

To minimize material waste, the Optimizer evaluates opening inventory, time, material expiry dates, planned inbound deliveries, manufacturing, and then prioritizes materials with the shortest expiration dates. Merging the Bill of Materials (BOM) reveals the decomposition of materials as sub-components, building a multi-level bridge to the exact quantity of components needed for each material.

Capacity is calculated per product, per production day, and by considering the capacity constraints of each machine (as per manufacturer specifications) as well as preparation time, cleaning, and changeover.

Then the data is mapped to the optimization algorithm (leveraging a native HANA R linear programming algorithm via the SAP Profitability and Performance Management R Remote Function Adapter), and an iterative optimization of product mixes is performed.

The resulting product mixes (ranked and optimized) can then be analyzed further in SAC.

The combined solution of SAP Dairy Management with the Dairy Optimizer of SAP Profitability and Performance Management hence allows the optimization of dairy product portfolios across raw material availability networks under the constraints of supply, capacity, costs, margin, demand, and other factors. With the msg solutions, dairy companies can work more efficiently, achieve higher yields, improve the accuracy of their financial forecasts, and realize higher margins.